How Temperature and Humidity Affect Concrete Coating Installation: What Texas Homeowners Should Know

In the diverse climate of Texas, homeowners face unique challenges when installing concrete coatings on their driveways, patios, and garage floors.

Temperature and humidity play crucial roles in determining the success of concrete coating projects, affecting everything from curing times to long-term durability.

Whether you’re in the humid Gulf Coast region or the drier areas of North Texas, understanding how local weather conditions impact concrete coating installation can save you thousands in potential repairs and ensure a beautiful, long-lasting finish.

This guide explores the critical relationship between Texas weather patterns and concrete coating installation, providing homeowners with essential knowledge to make informed decisions about their concrete projects.

Understanding Texas Climate Zones and Their Impact on Concrete

Texas spans multiple climate zones, each presenting unique challenges for concrete coating installation.

From the humid subtropical climate of East Texas to the semi-arid conditions of West Texas, understanding your specific region’s weather patterns is essential for successful concrete coating projects.

Gulf Coast Humidity Challenges

The Gulf Coast region of Texas, including Houston and Galveston, experiences extremely high humidity levels year-round, often exceeding 75% relative humidity.

This excessive moisture creates significant challenges for concrete coating installation.

High humidity slows evaporation rates, extending curing times for epoxy and polyaspartic coatings.

According to a 2023 study by the American Concrete Institute, installation in humidity above 85% can increase curing time by up to 72 hours and potentially compromise adhesion.

For homeowners in coastal areas like Corpus Christi or Galveston, moisture mitigation strategies become essential.

Professional contractors like Grizzly Concrete Coatings typically use moisture meters to assess concrete conditions before installation and may recommend specialized primers designed for high-humidity environments.

Central Texas Temperature Fluctuations

Central Texas cities like Austin, San Marcos, and New Braunfels experience dramatic temperature fluctuations, especially during spring and fall.

These rapid changes can create condensation issues on concrete surfaces, particularly when warm days are followed by cool nights.

Temperature swings of 30°F or more within 24 hours are common in Central Texas during transitional seasons.

These fluctuations can cause moisture to condense on concrete surfaces, creating a thin film of water that prevents proper adhesion of coatings.

Professional installers monitor dew point calculations and schedule installations during periods of stable temperatures to avoid these issues.

North Texas Freeze-Thaw Cycles

North Texas regions experience more frequent freeze-thaw cycles than other parts of the state.

These cycles can cause concrete to expand and contract, potentially creating microfractures that affect coating adhesion.

In cities like Dallas and Fort Worth, winter temperatures regularly drop below freezing at night while rising above freezing during the day.

The Texas Department of Transportation reports that concrete in North Texas can experience up to 30 freeze-thaw cycles annually.

This environmental stress makes proper concrete preparation and coating selection particularly important.

Flexible coatings with good elongation properties perform better in these conditions than rigid systems.

Critical Temperature Thresholds for Concrete Coating Success

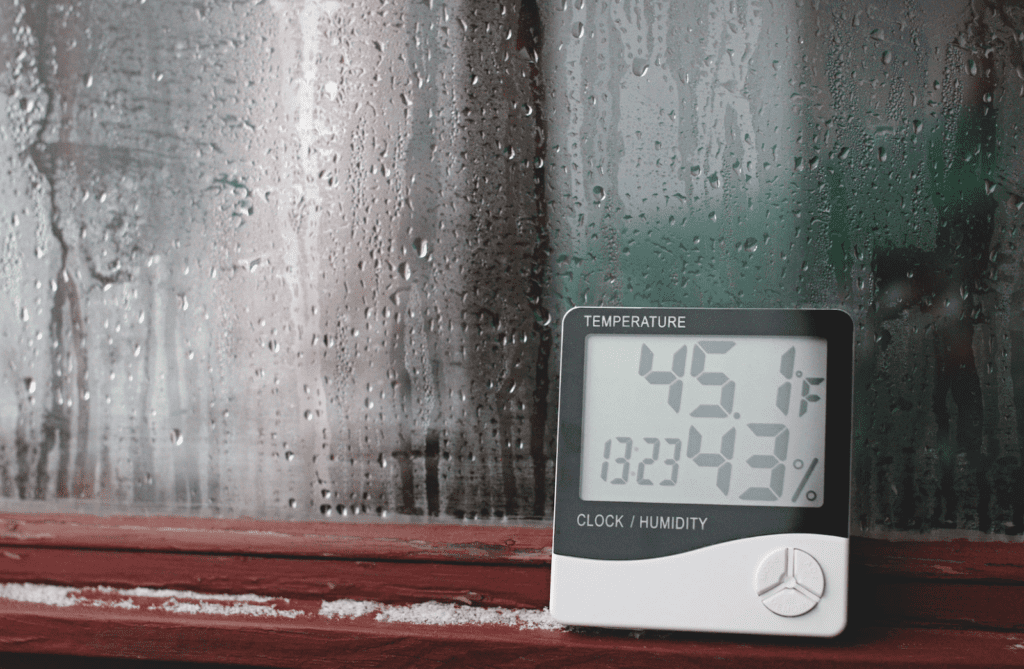

Understanding temperature thresholds is essential for successful concrete coating installation across Texas. Different coating systems have specific temperature requirements that must be strictly followed.

Minimum Temperature Requirements

Most concrete coatings require a minimum ambient temperature of 50°F for proper application and curing.

However, the concrete surface temperature is even more critical than air temperature.

The substrate should be at least 5°F above the dew point to prevent condensation issues during installation.

For polyaspartic coatings, which have gained popularity in Kyle and Wimberley homes, the minimum application temperature can be as low as 30°F, making them suitable for winter installation.

However, epoxy systems typically require warmer conditions, with minimum temperatures of 55-60°F for optimal results.

Maximum Temperature Limitations

Excessive heat poses significant challenges for concrete coating installation in Texas.

High temperatures accelerate chemical reactions, drastically reducing working time (pot life) for mixed coatings.

In summer months, when concrete surface temperatures can exceed 100°F, installation becomes particularly challenging.

In areas like Marble Falls and Dripping Springs, summer concrete temperatures can reach 120°F or higher in direct sunlight.

At these temperatures, epoxy systems may have less than 10 minutes of working time before beginning to harden.

Professional installers often work early mornings or evenings during summer months and may use ice baths to cool materials before mixing.

Ideal Temperature Windows by Season

Each season offers different optimal installation windows across Texas regions:

- Spring (March-May): Ideal in most regions, with moderate temperatures of 65-80°F and decreasing precipitation. Morning installations work best.

- Summer (June-August): Challenging throughout Texas. Early morning installations (before 8 AM) are recommended, with surface temperatures below 85°F.

- Fall (September-November): Generally optimal, especially October, with stable temperatures and lower humidity. Afternoon installations often work best.

- Winter (December-February): Suitable for polyaspartic systems in South Texas, but challenging for epoxy systems statewide. Afternoon installations between 1-3 PM typically offer the warmest conditions.

Humidity’s Role in Concrete Coating Adhesion

While temperature concerns often dominate discussions about concrete coating installation, humidity plays an equally critical role in determining project success, particularly in moisture-prone areas of Texas.

Measuring Concrete Moisture Content

Concrete moisture content directly impacts coating adhesion. Even fully cured concrete contains moisture that can migrate upward through the slab and potentially cause coating failure if not properly addressed.

This is particularly problematic in areas with high water tables, like parts of Houston and the Gulf Coast.

Professional installers use several methods to measure concrete moisture:

- Calcium chloride testing (ASTM F1869) – measures moisture vapor emission rate (MVER)

- Relative humidity testing (ASTM F2170) – uses in-situ probes to measure humidity within the concrete

- Electronic moisture meters – provide quick surface readings for initial assessment

For Texas homeowners, understanding that new concrete requires adequate curing time is essential.

Relative Humidity Guidelines for Installation

Industry standards recommend waiting at least 28 days after concrete placement before installing coatings. However, this may need to be extended in high-humidity environments like Bulverde or Spring Branch.

Relative Humidity Guidelines for Installation

Relative humidity (RH) in the air affects how quickly moisture can evaporate from concrete and coating materials. Most manufacturers specify maximum RH levels for installation:

- Epoxy systems: Generally require RH below 75%

- Polyaspartic coatings: Can tolerate higher RH, up to 85% in some formulations

- Polyurea systems: Offer the highest humidity tolerance, with some systems installable at up to 95% RH

In Texas, morning humidity levels often exceed these thresholds, particularly in eastern regions.

Professional installers monitor weather forecasts and plan installations during periods of lower humidity. They typically schedule installations in the afternoon hours during spring and fall.

Dew Point Considerations

Dew point calculation is perhaps the most overlooked aspect of concrete coating installation among DIY enthusiasts. When the concrete surface temperature drops to or below the dew point, moisture condenses on the surface, preventing proper adhesion.

In Texas cities like Boerne and Canyon Lake, evening dew point issues are common during spring and fall.

Professional installers calculate the dew point using temperature and humidity readings. They also ensure the concrete surface temperature remains at least 5°F above this threshold throughout the installation and initial curing period.

Seasonal Installation Guide for Texas Homeowners

Texas homeowners should consider seasonal factors when planning concrete coating projects. Each season presents unique challenges and opportunities depending on your specific region.

Spring Installation Best Practices

Spring offers generally favorable conditions for concrete coating installation across Texas, though with some regional variations. March through May typically provides stable temperatures between 60-80°F, ideal for most coating systems.

East Texas homeowners should be cautious of spring rains and resulting humidity spikes.

West Texas residents benefit from drier conditions but should monitor wind forecasts, as high winds can introduce dust and debris into wet coatings.

Central Texas homeowners face fewer challenges during spring, making it an optimal installation season.

For best results in spring:

- Schedule installations for mid-morning after dew has evaporated

- Check 7-day forecasts for rain probability

- Ensure adequate ventilation without excessive airflow

- Consider faster-curing systems if weather stability is questionable

Summer Installation Challenges

Summer presents significant challenges for concrete coating installation throughout Texas. Excessive heat accelerates curing, reducing working time and potentially causing bubbles, pinholes, and adhesion issues.

Surface temperatures can exceed 120°F in direct sunlight, well beyond most coating systems’ maximum recommendations.

If summer installation is unavoidable:

- Schedule work for early morning (5-8 AM)

- Use pop-up canopies to shade work areas

- Consider adding manufacturer-approved retarders to slow curing

- Store materials in air-conditioned spaces until immediately before use

- Use cooler-temperature water for cleaning and preparation

Fall: The Optimal Installation Season

Fall represents the ideal installation season across most of Texas. October is particularly favorable, with moderate temperatures, lower humidity, and minimal precipitation. Stable weather patterns reduce the risk of dew point issues and provide optimal curing conditions.

For fall installations:

- Mid-morning to early afternoon timing works best

- Monitor overnight temperature forecasts to ensure they remain above minimum thresholds

- Take advantage of lower humidity for better moisture evaporation

- Schedule projects for early fall to ensure complete curing before winter temperatures arrive

Winter Precautions and Limitations

Winter installations require careful planning and material selection. In South Texas, winter often remains mild enough for most coating systems. However, North and Central Texas experience freezing temperatures that can prevent proper curing.

Winter installation considerations:

- Polyaspartic and polyurea systems offer better cold-weather performance than epoxies

- Schedule installations between 11 AM and 2 PM when temperatures peak

- Allow extra curing time before exposure to traffic

- Use infrared thermometers to verify surface temperatures meet minimum requirements

- Consider temporary heating for garage installations

Professional vs. DIY: Weather-Related Considerations

The decision between professional installation and DIY approaches becomes particularly significant when considering weather variables in Texas.

Professional concrete coating contractors bring several advantages in managing weather-related challenges:

- Access to commercial-grade moisture meters and dew point calculators

- Experience interpreting weather forecasts specifically for coating applications

- Ability to adjust formulations for specific conditions (with manufacturer guidance)

- Knowledge of regional microclimate patterns that affect installation

- Access to climate-controlled storage for materials

DIY installers face additional weather-related challenges:

- Limited access to professional moisture testing equipment

- Restricted working hours based on personal schedules rather than optimal conditions

- Longer installation timeframes, increasing weather variability exposure

- Less experience recognizing early warning signs of weather-related issues

Long-Term Effects of Weather-Compromised Installation

Installing concrete coatings under suboptimal weather conditions can lead to significant long-term problems that may not be immediately apparent.

Understanding these potential issues helps homeowners appreciate the importance of weather considerations.

Installations performed in excessive humidity can lead to:

- Cloudy, hazy appearance in clear topcoats

- Reduced coating hardness and wear resistance

- Water spotting and whitening

- Delamination and peeling, typically beginning 6-18 months after installation

Temperature-related installation problems often manifest as:

- Bubbles and pinholes from accelerated curing

- Uneven gloss levels and color inconsistency

- Premature wear in traffic areas

- Cracking and splitting during seasonal temperature changes

According to a 2024 industry study, up to 68% of concrete coating failures can be attributed to environmental conditions during installation rather than product defects or substrate issues. This highlights the critical importance of proper timing and environmental controls during the installation process.

Maintenance Tips for Weather-Resistant Concrete Coatings

Once your concrete coating is properly installed, following region-specific maintenance practices can help extend its lifespan despite Texas’s challenging climate.

For Gulf Coast homeowners:

- Perform quarterly inspections for moisture-related issues

- Clean surfaces regularly to remove salt air deposits

- Apply additional UV-resistant topcoats every 3-5 years

For Central Texas homeowners:

- Inspect expansion joints annually for weather-related deterioration

- Address any drainage issues that cause water to pool on coated surfaces

- Consider applying cold-weather sealers before winter in northern regions

For all Texas regions:

- Clean spills promptly, especially during extreme temperatures

- Use manufacturer-recommended cleaning products only

- Schedule professional inspections every 2-3 years to identify early signs of weather-related deterioration

Properly maintained concrete coatings installed under optimal conditions can last 10-15 years in Texas environments, compared to just 3-5 years for improperly installed systems.

Take Action for Long-Lasting Concrete Coatings

Understanding how temperature and humidity affect concrete coating installation is essential for Texas homeowners seeking beautiful, durable results.

By recognizing your region’s specific climate challenges and planning installations during optimal weather windows, you can significantly improve your project’s outcome and longevity.

Grizzly Concrete Coatings specializes in weather-optimized installation techniques for Texas homeowners, ensuring your concrete coating project succeeds regardless of local climate challenges.

Our technicians are trained in advanced moisture testing and environmental monitoring to provide optimal results in every season.

Ready to transform your concrete surfaces with professional results that stand up to Texas weather? Contact Grizzly Concrete Coatings today for a free consultation and estimate.

Our experts will help you determine the ideal timing for your project based on your specific location and weather patterns.

Don’t let Texas weather compromise your concrete coating investment. Schedule your professional assessment today and enjoy beautiful, durable concrete surfaces for years to come.

Frequently Asked Questions

What is the ideal temperature range for installing concrete coatings in Texas?

The ideal temperature range for concrete coating installation in Texas is between 60-80°F with relative humidity below 65%. These conditions provide optimal working time and curing characteristics for most coating systems.

However, different coating types have varying requirements: epoxies generally need temperatures above 55°F, while polyaspartic coatings can be installed in temperatures as low as 30°F.

Surface temperature is even more critical than air temperature and should be at least 5°F above the dew point to prevent condensation issues.

How long should I wait after rain before installing concrete coatings?

After rainfall, you should wait until the concrete is completely dry before applying coatings. In Texas summer conditions, this might be as little as 24 hours, but during more humid seasons or in coastal areas, waiting 48-72 hours is recommended.

Professional contractors use moisture meters to measure the concrete’s moisture content rather than relying solely on visual assessment.

The ideal moisture vapor emission rate (MVER) should be less than 3 pounds per 1,000 square feet per 24 hours for most coating systems.

Can concrete coatings be installed during Texas summers?

Yes, concrete coatings can be installed during Texas summers, but with significant precautions.

Early morning installation (between 5-8 AM) is essential to avoid excessive heat.

Surface temperatures above 90°F can dramatically reduce working time and may cause bubbling or improper curing.

Professional installers often use pop-up canopies to shade work areas and store materials in air-conditioned spaces until immediately before use. Some contractors also add manufacturer-approved retarders to slow curing in extreme heat conditions.

How does humidity affect concrete coating installation in different parts of Texas?

Humidity affects concrete coating installation differently across Texas regions.

In Gulf Coast areas like Houston, high humidity (often exceeding 75% RH) slows evaporation rates and extends curing times. This can lead to cloudy finishes and potential adhesion issues.

In drier West Texas regions, low humidity may cause too-rapid solvent evaporation in some coating systems, potentially leading to bubbling or improper flow.

Central Texas experiences significant humidity fluctuations, requiring careful timing of installations.

Professional installers monitor both relative humidity and calculate dew points to determine suitable installation windows.

What are the signs that my concrete coating was installed in poor weather conditions?

Signs that concrete coatings were installed in poor weather conditions include:

- Cloudy or hazy appearance in clear topcoats (high humidity during installation)

- Bubbles or pinholes (excessive heat or moisture vapor)

- Soft spots or tacky areas that don’t fully cure (low temperatures during installation)

- Whitening or water spotting (moisture exposure during curing)

- Early delamination or peeling, especially at edges (dew point issues during installation)

- Uneven gloss levels or color inconsistency (temperature variations during application)

These problems typically begin appearing within 6-18 months after installation, though some may be evident immediately.

Frequently Asked Questions

What is the ideal temperature range for installing concrete coatings in Texas?

The ideal temperature range for concrete coating installation in Texas is between 60-80°F with relative humidity below 65%. These conditions provide optimal working time and curing characteristics for most coating systems.

However, different coating types have varying requirements: epoxies generally need temperatures above 55°F, while polyaspartic coatings can be installed in temperatures as low as 30°F.

Surface temperature is even more critical than air temperature and should be at least 5°F above the dew point to prevent condensation issues.

How long should I wait after rain before installing concrete coatings?

After rainfall, you should wait until the concrete is completely dry before applying coatings.

In Texas summer conditions, this might be as little as 24 hours, but during more humid seasons or in coastal areas, waiting 48-72 hours is recommended.

Professional contractors use moisture meters to measure the concrete’s moisture content rather than relying solely on visual assessment.

The ideal moisture vapor emission rate (MVER) should be less than 3 pounds per 1,000 square feet per 24 hours for most coating systems.

Can concrete coatings be installed during Texas summers?

Yes, concrete coatings can be installed during Texas summers, but with significant precautions.

Early morning installation (between 5-8 AM) is essential to avoid excessive heat.

Surface temperatures above 90°F can dramatically reduce working time and may cause bubbling or improper curing.

Professional installers often use pop-up canopies to shade work areas and store materials in air-conditioned spaces until immediately before use.

Some contractors also add manufacturer-approved retarders to slow curing in extreme heat conditions.

How does humidity affect concrete coating installation in different parts of Texas?

Humidity affects concrete coating installation differently across Texas regions.

In Gulf Coast areas like Houston, high humidity (often exceeding 75% RH) slows evaporation rates and extends curing times. This can lead to cloudy finishes and potential adhesion issues.

In drier West Texas regions, low humidity may cause too-rapid solvent evaporation in some coating systems, potentially leading to bubbling or improper flow.

Central Texas experiences significant humidity fluctuations, requiring careful timing of installations.

Professional installers monitor both relative humidity and calculate dew points to determine suitable installation windows.

What are the signs that my concrete coating was installed in poor weather conditions?

Signs that concrete coatings were installed in poor weather conditions include:

- Cloudy or hazy appearance in clear topcoats (high humidity during installation)

- Bubbles or pinholes (excessive heat or moisture vapor)

- Soft spots or tacky areas that don’t fully cure (low temperatures during installation)

- Whitening or water spotting (moisture exposure during curing)

About Grizzly Concrete Coatings

- Grizzly Concrete Coatings is a premier concrete coating contractor serving homeowners throughout Central Texas, including San Marcos, Wimberley, Kyle, Spring Branch, Dripping Springs, Marble Falls, Bulverde, Canyon Lake, New Braunfels, and Boerne.

- With extensive experience in Texas’s diverse climate conditions, our team specializes in weather-optimized installation techniques that ensure beautiful, durable results regardless of local environmental challenges.

- We provide comprehensive concrete coating services, including moisture testing, professional surface preparation, and custom coating solutions designed specifically for Texas weather conditions.

No responses yet